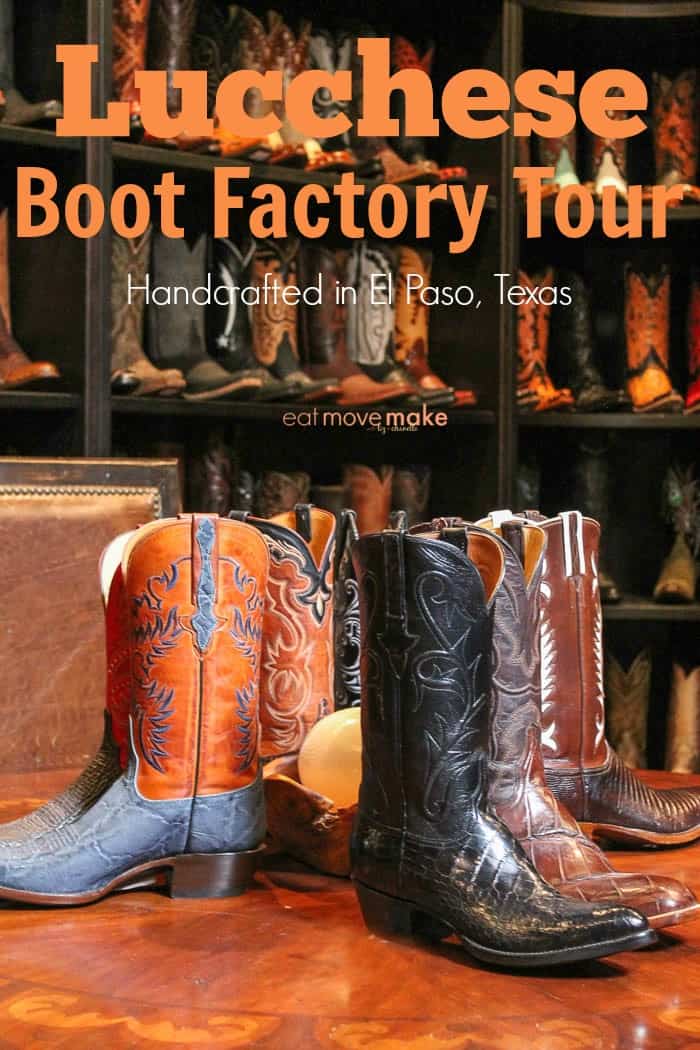

I’d always heard Lucchese made some of the very best cowboy boots, but when I took a Lucchese factory tour and saw the boot-making process from start to finish, it became very clear why their boots are held in such high esteem.

We spent about 1 1/2 hours in the factory, and to say I gained an appreciation for the art of handcrafted boots would be an understatement. I was blown away by the attention to detail and quality. The company readily admits they sell an expensive product, but they can back it up.

Lucchese takes no shortcuts, that’s for sure.

Lucchese History

Although you probably think of Lucchese and cowboy boots synonymously, Sam Lucchese actually began the company over 130 years ago by making cavalry boots for the U.S. Army.

In the 1940’s, he was commissioned by the government to make a pair of boots representing every state in the country. Many of them are back with Lucchese, some are in museums and some are being held for ransom. <~~~ That’s a joke. Kinda.

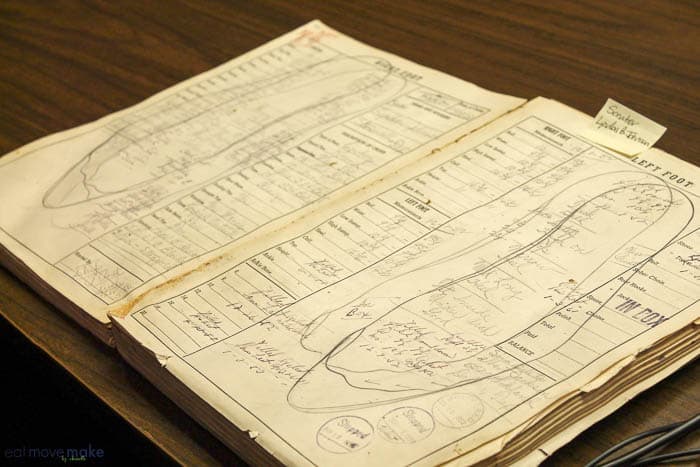

When the company began, customers would stand on “fit books” and have their feet traced. Sam would take measurements of those drawings and create a wooden last which he’d use to make a pair of boots.

Lucchese has a huge celebrity clientele, and they also make the official uniform boots for the Dallas Cowboy Cheerleaders. The largest pair of boots they’ve ever made was a size 25 for Andre the Giant.

It Begins with the Leather

At any given moment, you’ll find two or three million dollars of skins in the Lucchese leather room, but 88-89% of that raw material is a secondary by-product of meat processing. In other words, the animals have already been skinned for another purpose.

They only accept top grade leathers, and it’s all aniline-dyed (meaning the dye penetrates the entire skin, not just the outer layer). They work with cow, goat, ostrich, alligator, crocodile and many unusual skins like stingray, Indonesian python, sea bass, shark skin and once, even beaver tail.

The Making of a Lucchese Boot

After an order is placed, they have to pull skins and match scales, size of scales, texture, pattern etc. and find two skins that resemble each other. The skins are then die cut punched into the 9 or 10 pieces needed for a boot, and Lucchese saves 100% of the scraps.

Once the leather is cut, the pieces enter the sewing area where a pattern is stitched onto the leather.

I was captivated by the assembly process. From attaching the hung liner (which allows toes to move freely without affecting the exterior boot), to smoothing the seams, forming leather around the lasts, adding steel shanks, using lemonwood pegging to hold insoles and outsoles together, stamping Lucchese on the sole and “ironing” the boots… every step was fascinating.

Master Boot Making

If the custom boot order requires complex stitch work, it will all be handcrafted by Fidel, a master boot maker, who has been at Lucchese for over 40 years. He’ll hand place the paper patterns and hand-cut everything. On such intricate and detailed orders, Lucchese doesn’t want to rush the process, so they won’t estimate a completion date.

While a normal pair of boots takes about 6-8 weeks, there’s no prediction on time with Fidel’s highly skilled custom work.

Finishing Area

It’s in the finishing area where the leather tonal values can be adjusted with lightening, darkening, buffing or adding a high gloss finish. Lucchese’s signature color is black cherry, and we watched them deepen the red color to the customer’s specifications.

What makes Lucchese boots so expensive?

They’re Texas-made (USA-made), they pay an honest wage, and they don’t try to rush the process of boot making. Lucchese is more concerned with quality over quantity, so employees have no quotas, no minimums, and aren’t paid by the piece. They get a full day’s wage regardless of the number of boots they make. They also have strict quality controls in place. If any defect is spotted, it’s flagged and sent to the department to see if it can be fixed. If not, the boot needs to be remade. When I asked about the defect rate, he said it’s about 18-19%, but they pride themselves on that fact.

I guess it’s true that you get what you pay for, and Lucchese can stand proud that they’re absolutely worth every penny.

PS. These boots were made for walkin’ right on home to North Carolina with me. And so they did. I’m so grateful for the amazing behind-the-scenes Lucchese factory tour and for my first (but not last) pair of Lucchese boots.

Comments & Reviews

Those boots are amazing and I’m coveting them big-time! I would love to take a tour of their factory!

I’ve ALWAYS wanted a genuine pair of cowgirl boots and some of these materials are over the top. I definitely understand and appreciate the value in a real pair of boots now!

What a cool tour. Not only do you get to see how boots are made but i bet you could do some shopping. Two things i love shopping and learning.

OMG that is SO cool! I would love to take a tour of their boot factory!!

That is so amazing! I knew that boots often used snake skin, but I didn’t realize they were made with so many other kinds of skin as well.

I would LOVE to take a tour of a boot factory! I had no idea they used so many different types of leather in their boots. That is really amazing.

They will literally make anything into a boot! I can’t believe they use fish skin! Totally cool. This makes me want to go out and buy some boots.

This would be very interesting to me. I love seeing how stuff is made and anything is behind the scenes. Those cobra ones look scary.

This is so neat! I would have enjoyed watching it as well! The cobra boots creep me out too! I don’t like snakes so I wouldn’t want to touch those! Haha!!

Thank you for taking me along for the tour! I am from Arizona originally and everyone wore cowboy boots so I would love to go here and see it for myself.

I had actually never heard of this brand before (I live in Canada) but wow, it looks like amazing quality. My youngest daughter absolutely loves horse and has been wanting a good pair of boots – I’ll keep this brand in mind for when she is a little older.

Absolutely amazing! What intricate art that has to be put into every single pair. I appreciate footwear and apparel like this!

I love the boots representing every state. It would be wonderful it they got them all back someday!

We lived in El Paso for many years and my Father purchased all of his boots from Lucchese. He loved the individual attention he got and he knew he would always get a perfect pair of boots. My father has been gone many years, but we can’t seem to let go of his boots!

I love cowboy boots even though they aren’t a thing here in the east! What an awesome tour!!! I really enjoyed the pictures!

Now Texas pride is always with you.

What a neat tour to go on. I will have to check out this brand of boots, I could use a new pair.

That is so cool you got to see the boots being made! The request from someone wanting cobra heads at the toe is crazy to me. I’m so intrigued by all that goes into making a pair of boots now!

Those are some stylish boots! The craftsmanship is amazing. I was a boot girl growing up. Looking at some of these styles, I may need to revisit the boots!

I had no idea that Lucchese put so much effort into each boot. It sounds like the craftsmanship is definitely worth the money. It’s like owning a piece of art.

I have 2 pairs of Lucchese boots and they are my go to shoes. The are so comfortable and I love them. Living in Australia ?? every time we go on holidays it’s the first thing I do, is go n get a new pair of boots. My favourite are the 1883 ones.

I’m so jealous you were able to tour their factory. I first learned about Lucchese when I worked a couple of summers at Wall Drug and helped out in the boot department several times.

That would have been an interesting tour. I always love behind-the-scenes learning of how things are made.

This is absolutely the coolest! Those boots sound amazing- I LOVE the buckled ones!

The beaver tail skin has such a unique texture! And the color – totally not what I was expecting!

I love factory tours! These are great photos, they make me feel like I was there. The cobra head- gross!

Wow! What a cool tour! I’ve never seen joe boots were made like this and it’s such an interesting process.

Wow this is a near tour! The boots are pretty fantastic! I think they are great would love to tour a factory like this!

These boots are beautiful! I would love to be able to take a tour like this.

These are the coolest boots ever! I love the detail they have, and think it is cool you got to see them being made first-hand!

Oh wow this sounds like such a great place to visit. I bet it smells wonderful in there too!

It’s really impressive to see what is involved in making such a quality boot! I love and really appreciate a great pair and this brand definitely has a great reputation!

I’ve been wanting to add a pair of cowboy boots to my wardrobe. This looks like such a fun tour and makes me want a pair even more!

These boots are amazing. i love the great selections of designs and colors. I would love to do the Lucchese factory tour.

I have always wanted a pair of cow boy boots. These are all such beautiful work.

These boots would be an amazing gift for my Sister. She has always wanted pair. They are a work of art for your feet.

Wow! That’s pretty neat seeing how boots are made. I have a pair of boots, but I don’t wear a whole lot cause they hurt my feet.

One note is that Lucchese’s handmade boots will usually be higher in price than their machine-made line, but you are paying for the craftsmanship and tradition of boot-making.

These boots have superb craftsmanship and to own a pair would be just awesome! However, I would not want a boot made from the skin of any reptile, especially the cobra. Yikes. I’d settle for the beaver tail skin or the sea bass.

This is amazing!! Such a great opportunity how these boots are made! Great labor of love from these men! 😀 Would love to visit their factory too!

What an interesting tour this would be. My dad would enjoy visiting it. I might even go with him.

What an interesting process. I didn’t know it took that long for a pair of custom boots.

My husband loves his cowboy boots. He’s had his for so long and could use a new pair minus the cobra heads. That gave me shivers.

What an interesting place to visit. Just your post captivated me, so I am sure the actual tour would be so amazing! Those boots look amazing!!!

WOW! These are awesome boots!! Those designs are artwork! I would love to have a tour here one day!

These boots look so cool! I bet it was awesome to visit and see how the boots are made.

They have so many to choose from! I love that you showed the process. How cool!

A size 25?!?! Oh my lands! This was some really neat information.

I don’t think I’ve ever toured a boot factory. It’s really interesting to see how it’s made. I think that request with the cobra head is a little creepy!

I love the intricate designs. They are a true mark of real talented craftsmanship. However, if I had to have a pair of boots made in Lucchess, I would not want the snake skin or any reptile skin for that matter.

omg i would love to do this factory tour, looks awesome.

Wow, what a great history this company has — 130 years! Bootmaking is so interesting. It really is an art form. How cool to see behind the scene at the factory. I want a pair of cowgirl boots now! 🙂

~Lorelai

Life With Lorelai

Nice Boots

I Own a Pair of Alligator cowboy Boots

AWESOME!!!!

I’ve been wearing Lucchese for years .

I own a shoe repair and have been in business for 40 years or more so I know the quality and the detailing that goes into these boots.

Love to have another pair of their beautiful boots.

Excellent boots! I have several pair, my black lizards are 28 years old and they are like slippers. I use a leather lotion Lexol four times a year. I wear them every chance I get and friends say wow another new pair of expensive boots..nope just take care of them like one of my kids! Absolutely beautiful the best!

I own several pairs of boots including a pair of Luccheses. They are my most comfortable pair and are my go to pair if I’m going to do a lot of walking or prolonged standing. I always thought the factory was in San Antonio. Not a fan of El Paso, thank you.